Clutch Hydraulics

(To the right in diagram.) This first covers the inlet hole, and then proceeds to push fluid through the outlet pipe, to the slave. (Which in turn pushes a piston in the slave, and moves the clutch arm.)

52110495AF MOPAR Hydraulic assembly, hydraulic assy. Clutch master cylinder Factory Chrysler

The system—similar to a car's hydraulic braking system—uses a hydraulic master cylinder to create line pressure plumbed (usually) to an internal hydraulic release bearing (HRB) positioned on.

Volvo 240 Hydraulic Clutch Info.

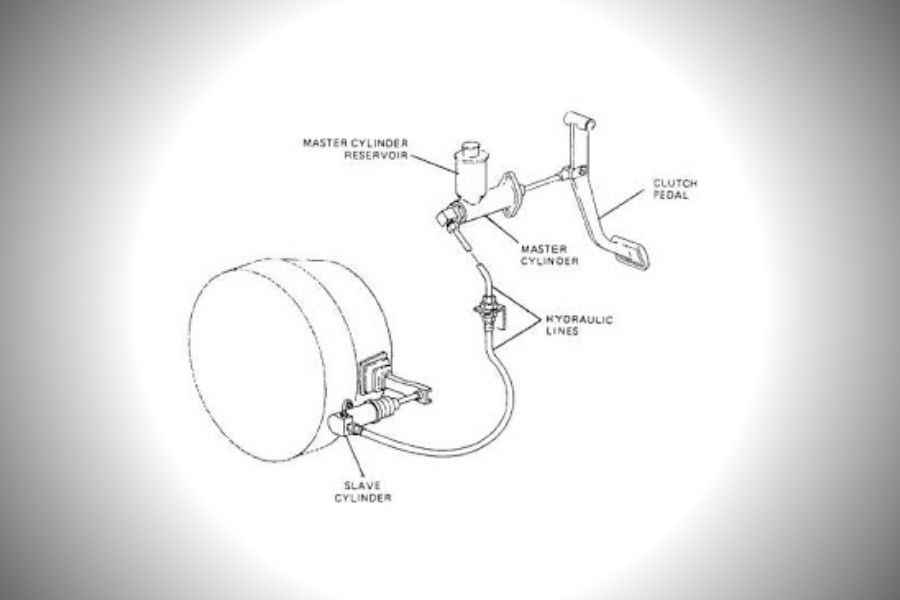

A hydraulic clutch system is a crucial component of a vehicle's transmission system, allowing for smooth and precise shifting of gears. Understanding the various components of this system is essential for diagnosing and maintaining the clutch system.

Hydraulic Clutch Components, Working, Advantages, Disadvantages & Applications [PDF]

The Basics Essentially, a clutch works by means of the gear shift lever or stick. You press the clutch down with your foot, and that causes the flywheel to move. This works with the pressure plate, disengaging the clutch disc and stopping the driveshaft from turning. The plate then releases and re-engages in the gear you've selected. Hydraulics

SWEM Hydr Clutch Tech Article

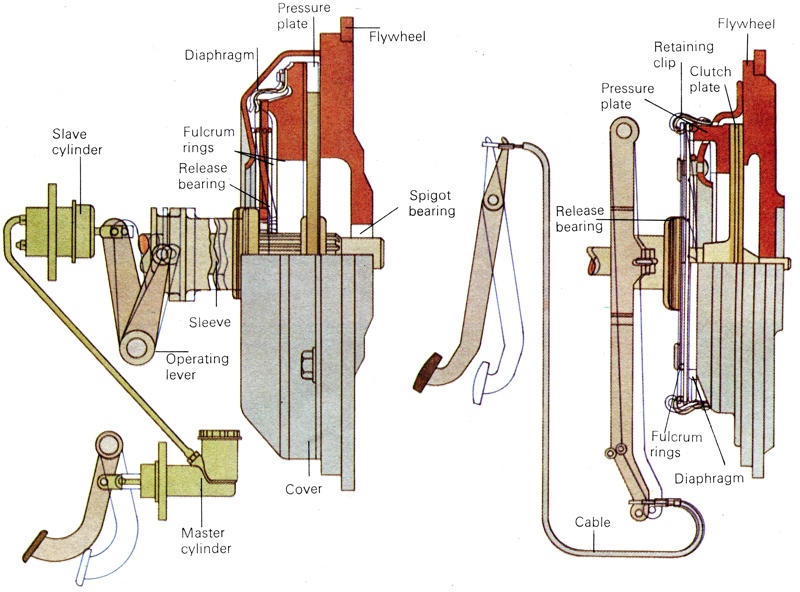

The below figure shows the diagram of a hydraulic clutch system used in an automobile. It consists of the following parts. 1) Flywheel: The flywheel is connected to the engine crankshaft.

52107652AM Mopar Hydraulic control. Clutch actuator. Controlshydraulic, clutchleft Mopar

Dry Cone clutch External Internal Centrifugal Clutch Semi-centrifugal clutch Conical spring clutch or Diaphragm clutch Tapered finger type Crown spring type Positive clutch Dog clutch Spline Clutch Hydraulic clutch Electromagnetic clutch Vacuum clutch Overrunning clutch or freewheel unit Read also: What is clutch and how it works?

92067510 GM Pipe. Hydraulic clutch reservoir. Cylindershydraulic Wholesale GM Parts Online

1. At some point a "high performance" clutch was installed. One way to get a clutch to hold more power is to give the pressure plate more spring rate enabling it to clamp harder onto the disc to keep it from slipping. This in turn makes it harder to push in and that translates all the way back up to the pedal. 2.

Mastering the Basics of Hydraulic Clutch Systems

Introduction International® has introduced a new hydraulic clutch system to replace the traditional mechanical clutch linkage. This system is standard on the 2010 ProStar® and LoneStar®, and optional on the TranStar® and WorkStar®.

Know How Selecting your clutch Repco New Zealand

Diaphragm clutch Clutch plate Surface of friction Pressure plate Master cylinder Slave cylinder & pushrod Flywheel Diaphragm springs Splined sleeves

52107652AC MOPAR Hydraulic control. Clutch actuator. Controlshydraulic Factory Chrysler

Using an aftermarket reproduction clutch pedal as the example, dimension #1 is 13.25 inches. There are two different stock pushrod holes available (measurement #2): three inches and 3.625 inches. To determine pedal ratio, divide figure #1 by #2. Here's how the ratios look for our example: 13.25 / 3 = 4.41 ratio. 13.25 / 3.625 = 3.63 ratio.

Adjusting a hydraulic clutch Tips and DIY tricks

The hydraulic clutch is what delivers the gear changes, and if it's not working you're going to find yourself driving in one gear - not for long, though. You'll have to get it checked out by a mechanic. To keep the hydraulic clutch problem-free, the best thing to do is avoid the practice known as "riding the clutch."

Clutch Hydraulics

Specifications Important specifications to consider when selecting a hydraulic clutch include but are not limited to: Torque Rating —The maximum torque rating for the clutch should equal or exceed the application's requirement. Power —The maximum power rating for the clutch. Speed —The maximum rotary speed rating.

15594156 Hydraulic Clutch Reservoir. GASKET. SEAL Wholesale GM Parts Online, Louisville KY

In the diagram below we can see the main components of a hydraulic clutch actuation system. Image: Clutch components with actuation system dual mass flywheel clutch cover mechanical releaser pedal vibration damping device clutch master cylinder (CMC) plastic clutch pedal clutch slave cylinder (CSC) clutch (friction) disc

Hydraulic Clutch Linkage Keeping in touch with the clutch

I. Hydraulic Actuation Wet or Dry Operation. Schematic # 1: Displays a typical circuit diagram for a hydraulically actuated wet or dry-running disc clutch. The pump (C) draws the oil through the filter (D) from the reservoir (H) and passes it under pressure to the operating pipeline. The operating pressure is adjusted by the limiting valve (E).

How To Adjust Your Clutch

Most cars use a friction clutch operated either by fluid ( hydraulic ) or, more commonly, by a cable. When a car is moving under power, the clutch is engaged. A pressure plate bolted to the flywheel exerts constant force, by means of a diaphragm spring, on the driven plate . Earlier cars have a series of coil springs at the back of the pressure plate, instead of a diaphragm spring.

How to Replace the Hydraulic Clutch Assembly

The hydraulic clutch system is a critical component in many vehicles, playing a pivotal role in the transmission of power from the engine to the wheels. This article delves into its history, classifications, advantages, and maintenance practices. History and Classification of Hydraulic Clutch Systems